Products

Commercial Gas Heating Stirring Sandwich Pot Jacketed Pot Cooking Pot

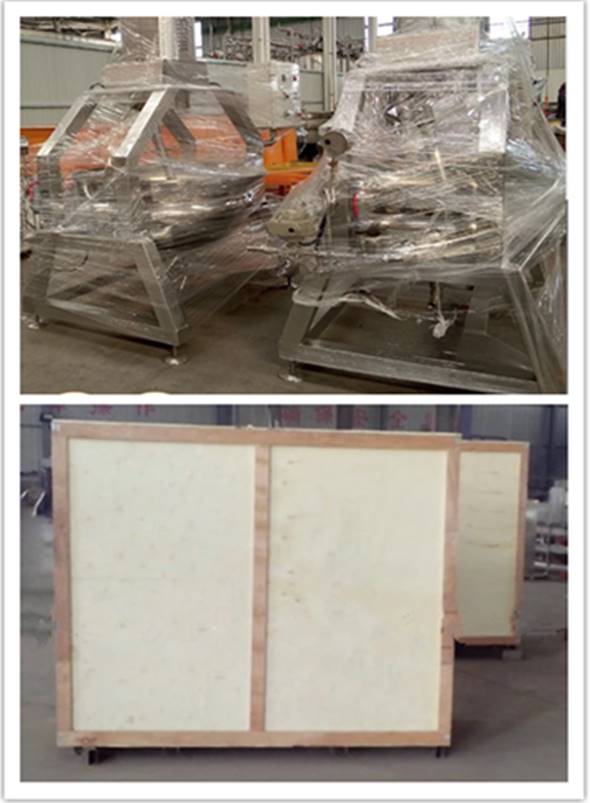

MOQ 1 Set Port Qingdao Packaging Standard export plywood case packaging for small machine ,for huge machine will be nude package. Lead Time 15-20 days after get deposit

Description:

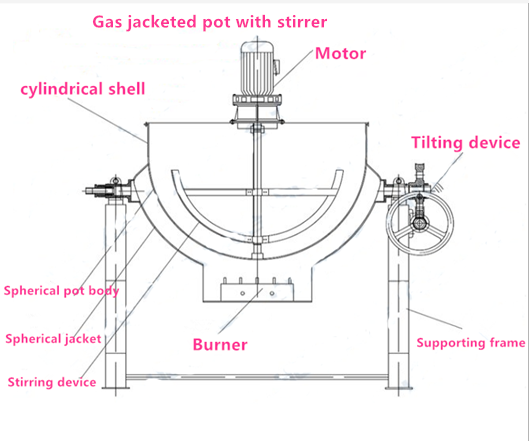

1. Short introduction of this machine:

This gas pot can be only tilting type ,customer can choose with stirrer or without stirrer, it is mainly composed of pot body and tilting frame, this pot use gas(liquefied gas, natural gas, pipeline gas ) as the heat source , the pot body can be tilted and dump the material out, it is very easy to operate and wash.

2. Features of this machine

Heating area is big ,Burning completely,smokeless dust-free, a small amount of carbon deposition, no environmental pollution, Flame temperature can be adjusted at your will, the heating is even and the heating temperature is easy to control ,the highest temperature can hit 300 degree Centigrade, Reasonable structure, easy operation, Thermal efficiency is high and energy saving ,strong fire, the thermal efficiency is about 25% higher than similar products .

Fuel:liquefied pertroleum gas, pipeline gas, natural gas, oil is strictly prohibited,

Gas consumption :about 25% lower than similar products.

Material boiling time is short,

3. Technical parameters:

|

Item# |

ZY-R100 |

ZY-R200 |

ZY-R300 |

ZY-R400 |

|

Volume(L) |

100L |

200L |

300L |

400L |

|

Diameter(mm) |

700 |

800 |

900 |

1000 |

|

Material |

SUS304 |

SUS304 |

SUS304 |

SUS304 |

|

Gas species |

liquefied pertroleum gas, natural gas |

liquefied pertroleum gas, natural gas |

liquefied pertroleum gas, natural gas |

liquefied pertroleum gas, natural gas |

Above technical parameter is only for your kindly reference ,it is standard parameters ,we will customized this machine for you based on what products you make and adjust the technical parameters accordingly.

4. Detail show of this machine:

5. APPLICABLE SCOPE

It is widely used for food processing , candy, pharmacy, dairy, liquor, cakes, drinks, sweetmeats, tinned food and so on, can also be used for large-scale restaurant or Cafeteria boiling soup, cooking meat and congee, etc.

6. How to use this machine:

Open the gas valve, ignite the gas, manually adding the cooking oil to the pot, when the oil temperature reaches the cooking temperature, adding right amount of food materials, manually stirring to make the food material heat evenly in the pot ,when finish cooking ,turn off the gas valve, turn the handle, through the drive device of worm gear and worm , tilting the pan body and pour the cooked food material into another container.

7. the advantages and disadvantages of gas heating /steam heating/electric heating jacketed pot:

Gas heating sandwich pan:

(1) burn completely, no smoke, no dust, small amount of carbon, no environmental pollution.

(2) the flame temperature can be adjusted at will, the highest temperature can reach 300 ℃ or so.

(3) reasonable structure and convenient operation.

(4) strong and energy saving, fierce fire, and increased thermal efficiency by about 25% compared with similar products.

(5) fuel: liquefied petroleum gas, pipeline gas, natural gas, oil is forbidden to use.

(6) gas consumption: about 20% lower than similar products.

Steam heating sandwich pot:

steam heating speed is quick, the normal temperature water heated to boiling steam only takes about half an hour or so, but it need to have an independent medium and high pressure steam system(need to equip with a boiler) ,the cost is higher, the advantage is that the heating speed is quick.

Electric heating sandwich pot:

the advantage is it is cheap, but the speed of heating is slower to realize the non-pressure heating, the heating temperature can reach 260 degrees.

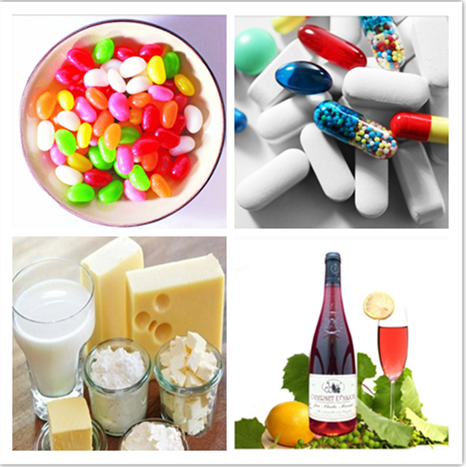

8. Packaging & Delivery

Packaging Details

Standard export plywood case packaging for small machine ,for huge machine will be nude package.

Delivery Time

Shipped in 20- 30 days after payment

9. Our Services

10. Payment:

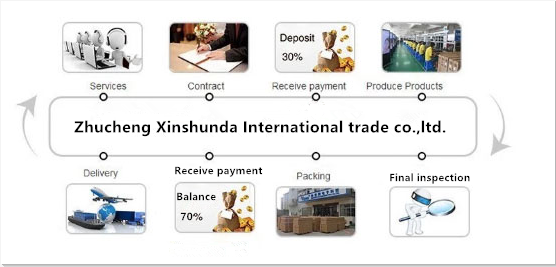

T/ T,please arrange pay us 30% as deposit to begin the bulk production,and for balance ,you can pay us after your final inspection and before we book vessel for you.

9. Delivery time:

We will deliver within 20-30 working days after receiving deposit payment.

10. Warranty period:

All our machine is with one year warranty. Within warranty time . Machine breaking caused by machine

itself design defect , we are responsible for it .we can provided free charge of breaking part, .If machine

breaking caused by human factor , user need take responsibility for it , we will provided technical support .

After one year warranty, we will provide spare parts with reasonable cost.

11. After-sales Service:

(1) Before deliver the machine, we will test and adjust everything properly.

(2) Once all is done, we will contact customer to make final inspection to our factory ,if customer not available ,we will make detailed picture for customer to confirm for delivery.

(3) working manule will be provided with the machine, so that clients can use our machine without difficulty.

(4) Any problems occur while using, we will provide profession advice and technical support ASAP.

(5) Spare parts of the machien is provide whole serving life with resonable price.

12. Our customer:

13. Short introduction of our factory

Our factory is found in year 2005 and is main in jacket pot and sterilization equipment product design ,research and development, After years’ efforts ,we have grown to be a very professional supplier for the jacketed pot and sterilization equipments in China. Our factory has passed ISO9001 quality system certification, and has the national pressure vessel manufacturing qualification (certificate number: TS22372142015), there are more than 100 employees working in our factory and 37 is senior technical management personnel, our factory covers an area of more than 13000 square meters and producing workshop area covers about 8000 square meters .Our factory has advanced machining center, automatic welding center and complete set of inspection equipment. Main products are: computer automatic/semi-automatic Double-pot water bath type sterilization pot , the computer automatic/semi-automatic top spray and side spray type sterilization kettle, rotary autoclave, double door autoclave, and tilting type, fixed vertical, stirring type sandwich cooking pot and so on .these machines can be widely used in all kinds of meat products, bean products, milk products, egg products, seafood, drinks products, snack food products cooking , sterilization and processing, also be used in agricultural products deep processing and chemical medicine production, etc .

By now our machines has exported to many countries such as Korea, Mongolia,Australia, Canada, Indonesia ……, we got highly recognization from these customers ,and would like to export more and more our machines to the foreign countries and build cooperations with more customers, we believe our quality/service will make you feel comfortable and would like build long-term cooperation with us . Give us a chance ,we will give you a surpise!

14. If any need for our machines or any questions for our machine, pls kindly contact me as below :