Products

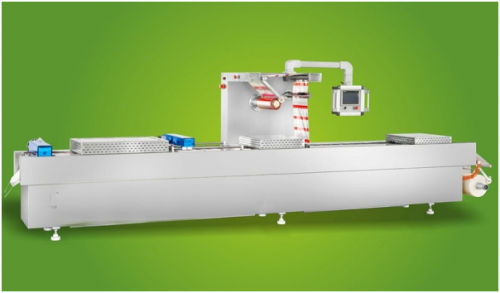

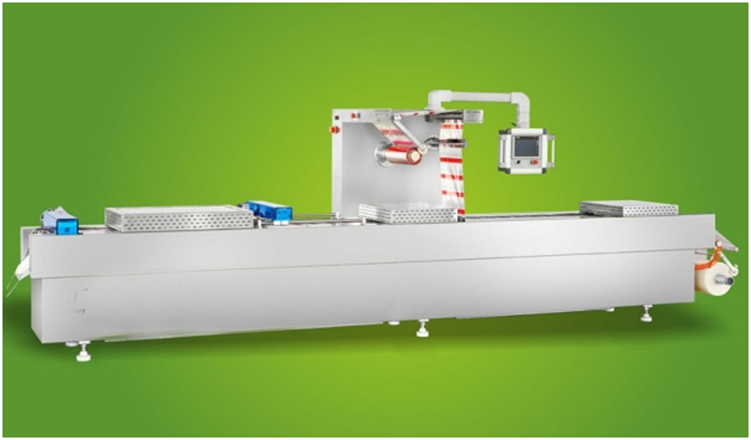

Automatic Continuous Stretch Film Vacuum Packaging Machine/vacuum Sealer

MOQ 1 Set Port Qingdao Packaging Standard export plywood case packaging for small machine ,for huge machine will be nude package. Lead Time 15-20 days after get deposit

Description:

Automatic continuous stretch film vacuum packaging machine

1. Features of the machine:

1. Equipped with imported brand Panasonic or GH10.4 Inches (Original German SIEMENS-TP900) color simulation touch screen, Push-pull design, more convenient to operate.

2.According to the user’s demand for products to equip with imported Panasonic brand MHMD042GIU or(GermanSIMMENS-V80) servo control and printing device or not.

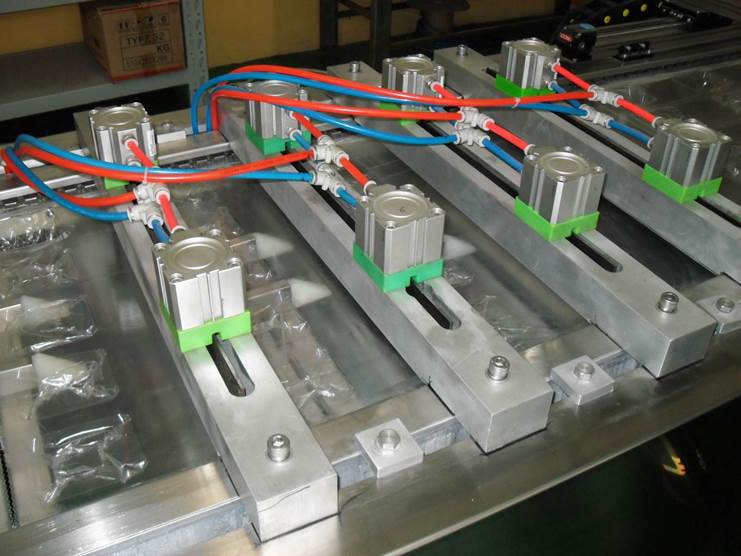

3. Upper and lower separation type mold, high strength, corrosion resistance, the design is more reasonable, convenient and quick to assemble and disassemble.

4. The Taiwan TYC or(Italy original REGINA) open type chain film clamp. To ensure the clamping force, the transmission is precise, service life is long.

5. Using the independent crosscutting, single pole can be moved and adjusted, Computer centralized control, can choose to turn on or turn off the single pole on the touch screen.

6. Selection of Germany imported original BUSCH, LEYBOLD, Rietschle vacuum pump, has the characteristics of high air pumping speed, high vacuum degree, long service life etc.

7. Use imported Panasonic brand MDME 102GCG, 152 or (original German SIEMENS-S110, S150) servo high-speed, high precision film design

8..Equipped with imported Panasonic brand LX-111 or(America original BANNER R58)high sensitive three color standard photoelectric sensor, high precision in positioning each picture on the products, To beautify the appearance of products ,improve product quality.

9. Temperature control adopts imported Panasonic brand FCX-TC2 or (original German SIEMENS-S7-1200)intelligent temperature control module, According to product requirements set temperature on the touch screen.

10. Packaging machine body adopts one-time extrusion forming aluminum alloy,it has high strength, good corrosion resistance ,not easily deformed.

11.the use of imported Japanese original SMC electromagnetic value,the vacuum electromagnetic valve,Beautiful appearance, low air consumption, low noise ,durable,effectively improve the performance and service life of equipment.

12. Waste recycling adopts adjustable torque motor system, the scrap recycling is more clean,it is more convenient and noiseless,

13,Upper and lower membrane using induction type automatic brake and tension system,and is equipped with a transverse adjusting handle ,adjusting the packing film direction at any time.

14. The machine is equipped with a power lack of phase, phase inversion, high voltage, low voltage, power leakage protection system, easy operation and adjustment. Molding room, heat sealing room, cross-cutting knife, longitudinal knife all are installed safety switch and protective cover, The machine will automatic stop if any fault happen and show the cause of the problem

2. Main technical parameter:

|

Item# |

Bottom mould width(MM) |

Top Mould width(MM) |

vacuum degree |

power supply(V/HZ) |

average power(KW) |

outline dimension(mm) |

weight of machine(kgs) |

packing speed(Every minute) |

Cooling water |

Compressed air |

|

DLZ-320 |

322 |

293 |

≤ 200 |

380/50 |

8 |

3600x780x1760 |

950 |

4-6times |

≥ 0.15MPa |

≥ 0.5MPa |

|

DLZ-420 |

422 |

393 |

≤ 200 |

380/50 |

10-12 |

4850x880x1860 |

1380 |

4-6times |

≥ 0.15MPa |

≥ 0.5MPa |

|

DLZ-520 |

522 |

495 |

≤ 200 |

380/50 |

12 |

7000X1000X1800 |

2200 |

4-6times |

≥ 0.15MPa |

≥ 0.15MPa |

Attention: above technical parameters will change based on customer’s detail choice, we can confirm all details before give us firm order.

3. Advantages of this machine

1. Convenient to operate and high efficiency

2. Scrap recycling, more cleanly

3. Transmission is more precise

4. High vacuum degree

5. Low noise, high technology

6. Long service life

7. Safe and low fault rate

8. Multi rows design keep the yield increase

4. Detail show of this machine:

5. Scope of application:

This machine is suitable for all kinds of food, meat, seafood, fruits and vegetables, medical equipment, injection needle, infusion products such as vacuum, nitrogen filling, and plastic / fitted hard plastic packaging.

The packing speed is two times higher than that of the traditional vacuum / nitrogen filling packaging equipment.

6. Packaging & Delivery

Packaging Details

Standard export plywood case packaging for small machine, for huge machine will be nude package.

Delivery Time

Shipped in 20- 30 days after payment if no stock, if machine is available, we will ship it out within 7 days

7 .More kinds of vacuum packaging machine for your kindly choose:

If you don’t know which one to choose ,just advise me below information:

1. What will you pack with this machine?

2. What is your wanted production capacity per hour?

3. Is your packed item with water or not?

4. What is the size of your used packing bags including length X width x height.

5. What kinds of vacuum pump would you like to use? Germany Busch or leybold or our domestic brand vacuum pump?

After get these information, we will help you to work out the most suit you vacuum packaging machine and advise you the detail technical parameters of this machine.

8. Payment:

T/Please arrange pay us 30% as deposit to begin the bulk production, and for balance, you can pay us after your final inspection and before we book vessel for you.

9. Delivery time:

We will deliver within 20-30 working days after receiving deposit payment.

10. Warranty period:

All our machine is with one year warranty. Within warranty time. Machine breaking caused by machine itself design defect, we are responsible for it .we can provided free charge of breaking part, .If machine

Breaking caused by human factor, user need take responsibility for it, we will provided technical support.

After one year warranty, we will provide spare parts with reasonable cost.

11. After-sales Service:

1. Before deliver the machine, we will test and adjust everything properly.

2. Once all is done, we will contact customer to make final inspection to our factory, if customer not available, we will make detailed picture for customer to confirm for delivery.

3. Working manual will be provided with the machine, so that clients can use our machine without difficulty.

4. Any problems occur while using, we will provide profession advice and technical support ASAP.

5. Spare parts of the machine is provide whole serving life with reasonable price.

12. Our clients:

13. Short introduction of our factory:

Our factory is a professional manufacturer for vacuum packaging machine for over 15 years, we have one provincial level R&D team of 12 persons and 120 employees, and we have three production workshops and one processing workshop, equipped with 2 sets of international advanced machining center and dozens of plate shearing machine, polishing machine, bending machine, wire cutting machine, milling machine, drilling machine, lathe, punching machine and so on, completely solve the customer’s customized needs. Since working in this area , we are committed to building best products with advanced design experience and strict equipment manufacturing process. This enables our products always keep advanced level and more stable quality.

Our main products are: stretch film DLZ-320/420/520 automatic vacuum packaging machine, DZD - 1000/1100 type rolling vacuum packaging machine, DZ -800/850/900/2 s - 4 Connecting rob double room automatic vacuum packaging machine, conventional DZ - 700/600/500/2 s - 4 connecting rod double chamber vacuum packaging machine, we can customize the machine according to customer’s demand. So if you have any need for our machine ,just let me know and work with me closely ,I make sure you can buy the most suit you machines here with best price and best quality!

14. Any need for our products please contact with me as below: