Products

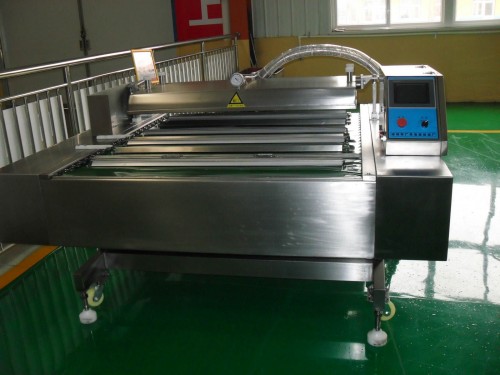

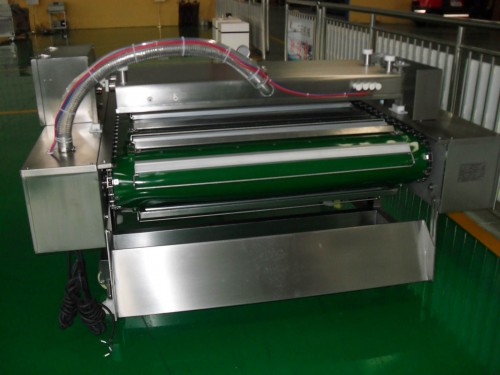

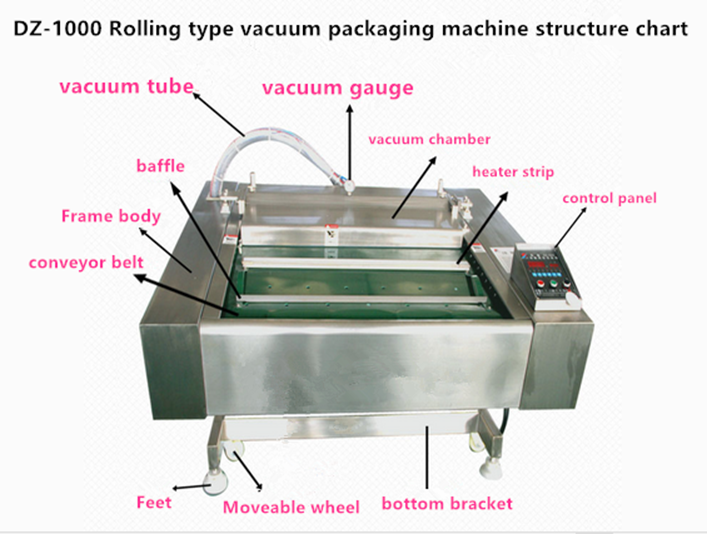

DZD-1000(1100)type Dual Seal Stripe Rolling Type Full Automatic Vacuum Packaging Machine Vacuum Sealer

MOQ 1 Set Port Qingdao Packaging Standard export plywood case packaging for small machine ,for huge machine will be nude package. Lead Time 15-20 days after get deposit

Description:

1. Characteristics of the machine:

1. All sus304 stainless steel material, no oxidation and rust

2. Full automatic control with touch screen, easy to operate

3. Avoid clamp hand device

4. Operation system fully sealed, the whole machine can be water flushed to clean except electrical panel.

5. The machine can be adjusted to four angles to meet different packing requirements.

6. Rolling type and continuous packaging, high work efficiency.

7. Frequency control, soft start, slow stop, conveying device, more accurate positioning.

2. Main technical parameter:

|

Item# |

weight ( no include pump) |

Power source |

Average power consumption |

Vacuum chamber size |

Effective sealing line size |

Efficiency ( times/hour) |

Outline dimension |

|

1000 |

460kg |

380V 50HZ |

5.8Kw |

1125x440x110mm |

1000x10 ( 8) mm |

240-360 |

1800x1400x1500mm |

|

1100 |

560kg |

380V 50HZ |

5.8Kw |

1225x550x110mm |

1000x10 ( 8) mm |

240-360 |

1900x1620x1500mm |

Attention: above technical parameters will change based on customer’s detail choice ,we can confirm all details before give us firm order.

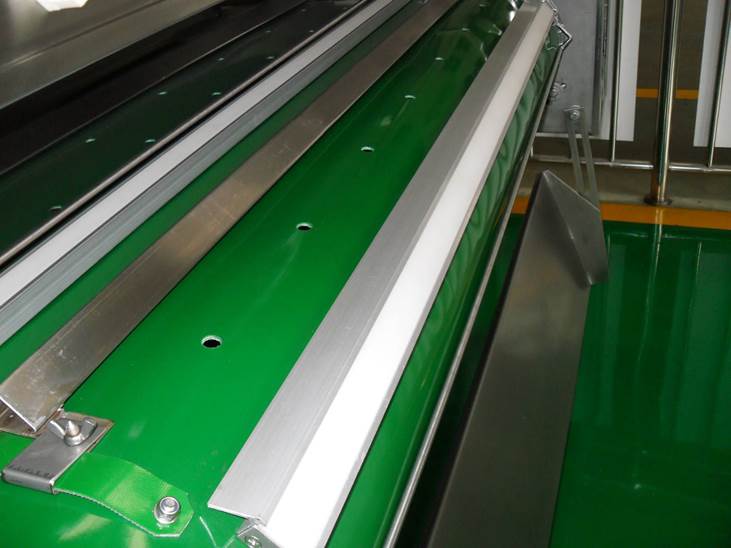

3. Detail show of this machine:

4. Scope of application:

Automatic continuous type vacuum packaging machine continuously operates through the rotation of the conveyor belt and applies to the product packaging of large scale productive enterprises. Depending on the size of the packed items and efficiency requirements ,one or two seals may be set within one chamber in order to improve working efficiency.

This machine is particular applicable to the preserved fruits , chemical medicine ,medicinal materials, electronic component, precision instrument, rare metal,pickled vegetables, frozen products, aquatic products, chicken products and other small packaging products. Can prevent oxidation and mildew to guarantee the quality, prolong storage life of the products.

5. Optional configuration:

·transport frequency converter is optional

· The spacing of sealing strips is optional.

·, computer board is optional.

· Vacuum pump is optional.

· The sealing strip width is optional.

6. Maintenance:

1, this vacuum packaging machine should be used under below conditions: temperature between -10℃ to 50℃, relative humidity not more than 85%, no corrosive gas /no dust /no explosive danger in the ambient air,

2. To ensure the vacuum pump is working properly for the vacuum packaging machine, . It is strictly prohibited vacuum pump motor reverse rotate... Please always check the oil level, oil level shall not be less than half of the oil window height, no more than three-quarters of the oil window height, When the pump oil mixed with water or other impurities or become black, should timely change oil. (Generally the oil should be changed once if it continuous work for one or two months, the oil should be 1# vacuum gasoline or 30# gasoline or engine oil.)

3. The impurities filter should be washed regularly (generally cleaning once by one to two months, if what packed is the fragment material please shorten the cleaning time accordingly).

4.Continuous working 2-3 months , the back cover should be opened to check and add lubricant oil to the sliding part and the switch .the connection joints on the heating rod should be added lubricant oil based on real status.

5. Check the decompression, filtration and oil mist three parts regularly, and make sure that the oil mist and oil cup are filled with oil (sewing machine oil), and there is no water in the filter cup.

6. The heating bar and the silicone bar should be kept clean, and no foreign matter should be adhered to so as to avoid affecting the quality of sealing.

7. On the heating rod, the layer of adhesive on the second layer of the heating piece is insulated, and should be replaced in time when damaged, so as not to short-circuit.

8. The user prepares the work gas source and the inflatable gas source themselves. The working pressure of the vacuum packaging machine has been set to 0.3mpa, and it is suitable for the user, do not adjust too much without special circumstances.

9. The vacuum packaging machine does not allow slant placement and impact during handling, and it is not allowed to put down and carry.

10. The vacuum packaging machine must have reliable grounding device when installing.

11. It is forbidden to put the hand under the heating rod to prevent the injury and please immediately cut off the power supply in case of any emergency.

12. When work, please first ventilate then power on, and the power will be cut off first then the ventilation will be shut down when the machine stops working.

7. Packaging & Delivery

Packaging Details

Standard export plywood case packaging for small machine, for huge machine will be nude package.

Delivery Time

Shipped in 20- 30 days after payment if no stock, if machine is available, we will ship it out within 7 days

8.More kinds of vacuum packaging machine for your kindly choose:

If you don’t know which one to choose, just advise me below information:

1. What will you pack with this machine?

2. What is your wanted production capacity per hour?

3. Is your packed item with water or not?

4. What is the size of your used packing bags including length X width x height.

5. What kinds of vacuum pump would you like to use? Germany Busch or leybold or our domestic brand vacuum pump?

After get these information, we will help you to work out the most suit you vacuum packaging machine and advise you the detail technical parameters of this machine.

9. Payment:

T/Please arrange pay us 30% as deposit to begin the bulk production, and for balance, you can pay us after your final inspection and before we book vessel for you.

10. Delivery time:

We will deliver within 20-30 working days after receiving deposit payment.

11. Warranty period:

All our machine is with one year warranty. Within warranty time. Machine breaking caused by machine itself design defect, we are responsible for it .we can provided free charge of breaking part, .If machine

Breaking caused by human factor, user need take responsibility for it, we will provided technical support.

After one year warranty, we will provide spare parts with reasonable cost.

12. After-sales Service:

1. Before deliver the machine, we will test and adjust everything properly.

2. Once all is done, we will contact customer to make final inspection to our factory, if customer not available, we will make detailed picture for customer to confirm for delivery.

3. Working manual will be provided with the machine, so that clients can use our machine without difficulty.

4. Any problems occur while using, we will provide profession advice and technical support ASAP.

5. Spare parts of the machine is provide whole serving life with reasonable price.

13. Our clients:

14. Short introduction of our factory:

Our factory is a professional manufacturer for vacuum packaging machine for over 15 years, we have one provincial level R&D team of 12 persons and 120 employees, and we have three production workshops and one processing workshop, equipped with 2 sets of international advanced machining center and dozens of plate shearing machine, polishing machine, bending machine, wire cutting machine, milling machine, drilling machine, lathe, punching machine and so on, completely solve the customer’s customized needs. Since working in this area, we are committed to building best products with advanced design experience and strict equipment manufacturing process. This enables our products always keep advanced level and more stable quality.

Our main products are: stretch film DLZ-320/420/520 automatic vacuum packaging machine, DZD - 1000/1100 type rolling vacuum packaging machine, DZ -800/850/900/2 s - 4 Connecting rob double room automatic vacuum packaging machine, conventional DZ - 700/600/500/2 s - 4 connecting rod double chamber vacuum packaging machine, we can customize the machine according to customer’s demand. So if you have any need for our machine, just let me know and work with me closely, I make sure you can buy the most suit you machines here with best price and best quality!

15. Any need for our products please contact with me as below: