Products

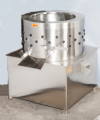

Chicken Plucker Feather Removal Machine For Poultry Abattoir Poultry Slaughter Machine Chicken Defeathering Machine

MOQ 1 Set Port Qingdao Packaging Nude Lead Time 15-20 days after get deposit

Description:

Quick Details

|

FOB Price: |

US$390-US$2,500 |

Condition: |

New |

|

Application: |

Poultry slaughterhouse or poultry abattoir or poultry farm for duck goose chicken turkey and so on |

Place of origin: |

Shandong ,China |

Poultry feather removal machine:

1. Products features:

This machine is convenient to operate,output is high, feather removal effect is very good ,after feather removal by this machine ,no need for person to remove the small feather any more,it is the most ideal chicken(duck) feather removal machine in China.

2. Main technical parameters:

|

Item# |

Power |

Weight |

Output |

Outline dimension |

|

QM-80 |

2.2KW/380V |

ABOUT 70KG |

300pcs/HOUR |

850X850X1300MM |

3. Detail show of this machine:

4. Operation Steps

1).Scald the poultry in hot water of 65-80 degree about 60-90 seconds after killing.

2). Then turn on the machine,put the scalded poultry into the machine (ginger,potato

and fish can put into the machine directly).

3). After 10 seconds working,turn on the water tap,and wash away the removed feather, then take out the poultry from the machine

4). The whole process of chicken plucking is about half minute.

5. Attention

1). Equip a leakage switch for the ground line.

2). Turn on the switch,and check if the machine running normally before using.

3). Wash the feather removal cylinder completely after using.

4). After long time using,please change the rubber finger when they are wearing or broken. So as to ensure the working efficiency.

5). After a period of using,if the rolling disc become slower,it might be the belt screw loose.

Then please adjust the nut on the machine base, but note it can't be too tight.

6. Application scope:

This machine is a ideal plucking machine suitable for supermarket, small and middle type slaughterhouse.

7. Packaging & Delivery

Packaging Details

Standard export plywood case packaging for small machine ,for huge machine will be nude package.

Delivery Time

Shipped in 20- 30 days after payment if no stock ,if machine is available ,we will ship it out within 7 days

8. A general introduction of the line ,it is only for your kindly reference .

The Chicken Slaughtering Line is consist of electrical stunning, manual killing, automatic scalding and plucking, semi-automatic evisceration (manual evisceration on conveying line or manual evisceration on the stainless steel table based on customer’s need), automatic pre-chilling, semi-automation dewatering, by-products processing and packing processing.

Below is a simple sheet for your kindly reference:

|

1 |

Killing conveyor line |

Chicken will be processed on this rail, it is main part for the main slaughter plant Production line. |

|

|

The distance of hangers is 8inch. |

|||

|

Stainless steel chain, guide rails, stainless steel hooks, nylon hanger |

|||

|

2 |

Electric stunning machine |

fiberglass reinforced plastic |

|

|

reliable and stable electrical devices |

|||

|

L=1.5METERS |

|||

|

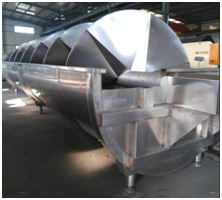

3 |

Scalding machine |

This machine is used to scald the carcass of the chicken to remove the feather easily; |

|

|

Thickness of Board: 2mm,Upper Cover Thickness :1.2mm,Supporting Leg Thickness:2mm. |

|||

|

Water temperature is between 58C° -61C° |

|||

|

use blower system and the the motor take water to form water falls to hold the chicken body to have best scalding results. |

|||

|

Power:6KW |

|||

|

4 |

A Frame refined Plucker |

This plucker is dedicated device for chickens ,there are 4 main parts: Depilation, regulation section, guide part, spray part. |

|

|

Principal part is stainless steel |

|||

|

Shape Size:3350*2350*2350 or customized |

|||

|

De-feather Machine consists of six boxes .Each line has 12 plates .Total 6 lines with72plates. |

|||

|

5 |

Automatic cut head machine |

this equipment use to automatically cut the chicken head on production line |

|

|

Principal part is stainless steel |

|||

|

6 |

|

this equipment use to automatically cut the chicken feet on production line |

|

|

Principal part is stainless steel |

|||

|

this equipment use dedicated accurate chuck location and have very good claw cutting effect |

|||

|

7 |

|

this equipment will be automatically take off the chicken feet from production line |

|

|

All body is stainless steel |

|||

|

8 |

|

This machine is to run the whole hanging rail |

|

|

including: motor , reducer , brackets and other drive components |

|||

|

Power:2.2KW By inverter power, run more smoothly. |

|||

|

9 |

Frequency converter |

Frequency Controlling Box. |

|

|

Stainless steel Box |

|||

|

10 |

|

To control the tightness of chain of production line to meet production requirements |

|

|

Stainless steel structure |

|||

|

11 |

|

This device can replace the previous precooling line to precool the chicken carcass |

|

|

This machine used to low down the temperature of carcass to keep the carcass good-looking and keep fresh in the forward process.The Thickness of the tank made of 3 mm stainless steel |

|||

|

Spiral Pushing Device is made by 2mm thick stainless steel. |

|||

|

Power 5.2kw/set |

|||

|

One set of Fan to make bubbles in the water in the tank efficiently so that improve cooling result and clean the carcass too |

|||

|

Buyer also need To Prepare cold Water or a set of ice machine, |

9. Payment:

T/T,please arrange pay us 30% as deposit to begin the bulk production,and for balance ,you can pay us after your final inspection and before we book vessel for you.

10. Delivery time:

We will deliver within 20-30 working days after receiving deposit payment.

11. Warranty period:

All our machine is with one year warranty. Within warranty time . Machine breaking caused by machine itself design defect , we are responsible for it .we can provided free charge of breaking part, .If machine

breaking caused by human factor , user need take responsibility for it , we will provided technical support .

After one year warranty, we will provide spare parts with reasonable cost.

12. After-sales Service:

1. Before deliver the machine, we will test and adjust everything properly.

2. Once all is done, we will contact customer to make final inspection to our factory ,if customer not available ,we will make detailed picture for customer to confirm for delivery.

3. working manual will be provided with the machine, so that clients can use our machine without difficulty.

4. Any problems occur while using, we will provide profession advice and technical support ASAP.

5. Spare parts of the machine is provide whole serving life with reasonable price.

13. Our clients :

14. About Us

Poultry slaughter line and supply single function poultry slaughter machines ,we can also supply supporting food equipments for poultry abattoir such as the vaccum packaging machine and sterilization retort and so on,If any need for our machines or any questions for our machine, pls.

15. Kindly contact me as below :